Crashworthiness refers to the degree of a motor vehicle’s vulnerability during an accident. Crashworthiness research programs test vehicles to find out how prone they are to make passengers and drivers defenseless in the event of a crash. This research has helped to improve automobile and bus design for greater safety.

The National Highway Traffic Safety Administration (NHTSA) began crash tests in the 1970s, and the Insurance Institute for Highway Safety (IIHS) began crashworthiness tests in 1995.

As a result of the kinds of tests done in these crashworthiness studies, as an example, we know that students are eight times safer in a school bus than a car. Interestingly, lap belts on school buses have been shown to provide little additional safety and may even cause abdominal injuries.

These organizations continually work on creating more specific tests that evaluate vehicle safety. Besides providing parameters for upgrades of federal safety standards, these tests provide an incentive for manufacturers – a car that tests well has a compelling selling point in the marketplace. Volvo bases its marketing almost solely on how well its cars test for crashworthiness.

If a car does not test well in all areas but meets federal safety standards, the manufacturer is more likely to be held liable in product liability lawsuits brought against it. If the manufacturer knows that its design puts consumers at risk, it could easily end up paying more for lawsuit settlements than it would have spent creating a safer, more expensive, design in the first place. Of course, a defect may not be a result of the design at all. Rather, it could be that the design was not followed properly in the manufacturing process.

There is no such thing as “crash-proof,” of course; no car is invincible. The idea is to determine what is likely to cause injury and to improve technology and design to avoid as many injuries as possible.

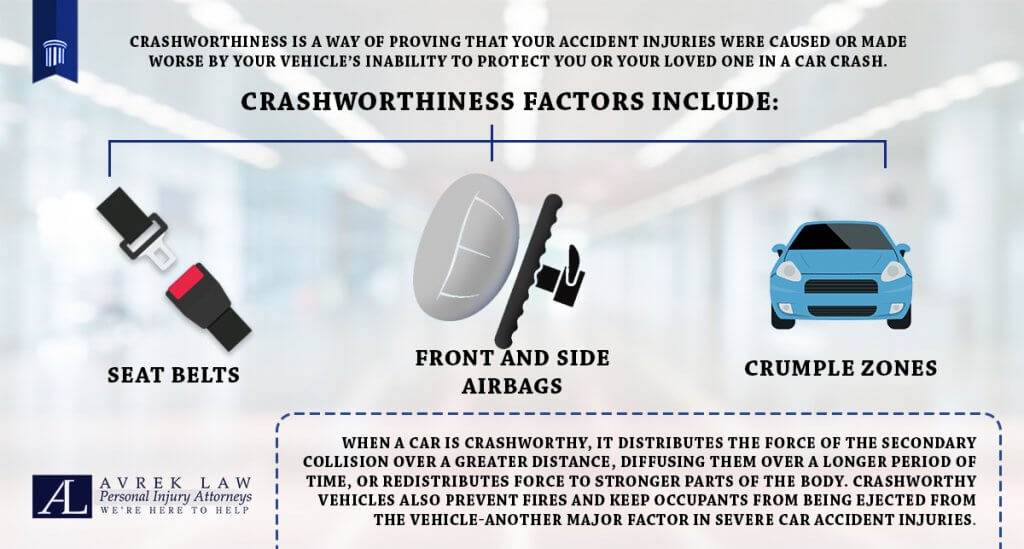

In a car, seat belts and airbags are the primary protective devices that determine a vehicle’s crashworthiness. Other factors include the strength of the car’s cabin against impact, which is evaluated from all possible angles of impact to determine the strength during a front collision, back collision, or side collision. The strength of the roof is also a consideration, as a weak roof is prone to collapse if the car rolls over.

Crashworthy vehicle designs are meant to (1) avoid “intrusion” into the compartment of the car, preventing crushing and collapse; (2) sufficiently keep passengers restrained in the vehicle; (3) prevent ejection of passengers and seats; (4) provide a secure interior within the car so that people are not injured by parts of the vehicle itself; (5) prevent the fuel system from catching fire.

The IIHS rates a car’s crashworthiness as (1) good, (2) acceptable, (3) marginal, or (4) poor. It performs front, rear, and side crash tests at high speeds, tests roof strength, and tests strength of seats and headrests.

The National Highway Traffic Safety Administration conducts front crash tests that impact the full width of the vehicle, while the IIHS performs frontal crash tests that vary depending on the degree of “overlap.” This refers to how much of the two cars in the collision make contact with one another during the accident.

In a “moderate overlap frontal crash test,” the car travels at 40 miles per hour. Forty percent of the car’s width crashes against an approximately two-foot tall barrier while a crash test dummy sits in the driver’s seat.

Most cars did not do well when the first moderate overlap frontal crash tests were attempted by the IIHS. As a result, car compartments were built stronger so that most makes of cars now perform well in the test.

A new frontal crash test for smaller overlaps was instituted in 2012. When just the corner of a vehicle experiences an impact with another car or an object, some seat belts and airbags do not perform adequately. In this test, the car again travels at 40 miles per hour and hits a five-foot-tall barrier with a crash test dummy in the driver’s seat. In this case, just 25 percent of the front of the car is involved in the collision.

Cars have what are called “crush zones” that guard against crushing during a collision. These zones are generally in the center of the car, while the small overlap frontal crashes occur toward the outer part of the car. As a result, these outer areas can be more vulnerable to crushing.

A main consideration in the test assessment is how much the driver and passenger seats have been intruded upon during the crash. This has to do with the strength of the car’s structure and how vulnerable different areas of the car are to being crushed.

Crash test dummies contain sensors that tell the engineers where injuries would be sustained in the crashes – the head, neck, chest, legs or feet. They also assess how much the dummy has moved during the crash. Greasepaint applied to the dummy’s head, knees, and legs shows what part of the vehicle made contact with the dummy. The paint will transfer to those parts of the car. The crash tests are also filmed and viewed for evaluation purposes.

The effects of a crash depend a great deal on what the car collides with. For example, if a lighter weight car collides with a heavier car, the heavier car will almost certainly fare better in terms of damage and the safety of the individuals inside.

One example is an accident with a minivan in which the entire seat was ejected from the vehicle when the side door was ripped off during the collision. Three girls were killed even though their seat belts were fastened. The other vehicle in the accident was a larger van, and the passengers in that larger vehicle were unharmed.

When a car accident occurs, an attorney who is well-versed in crashworthiness issues can evaluate whether product liability on the part of the manufacturer could be involved in the claim. Experts can be called upon to determine whether or not the car’s design or faulty construction in the manufacturing process is at least partially at fault for the injuries incurred in the collision.

If you have been injured in an auto accident and are on need of legal representation, please contact us.

How much is your case worth?

Get a free case evaluation